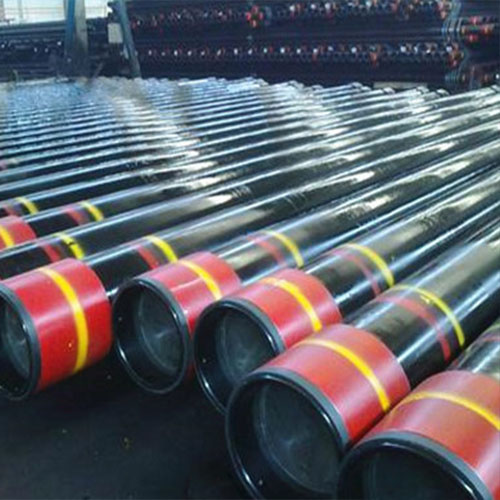

In oil and gas drilling, tubing and casing selection is critical to the success of the operation. Two commonly used oil casing materials are J55 and L80, both of which comply with the American Petroleum Institute (API) 5CT standard. Understanding the differences between these two materials is critical to making informed decisions in the oil and gas industry.

J55 tubing and L80 casing are both steel materials used in oil and gas well construction. The main differences between the two are mechanical properties and application areas. J55 is a low carbon steel grade commonly used in shallow oil and gas wells, while L80 is a medium carbon steel grade suitable for deeper and more demanding drilling environments.

One of the main differences between J55 and L80 pipe is their yield strength. Yield strength is a measure of the maximum stress a material can withstand without deforming. For J55 pipe, the minimum yield strength is 55,000 psi (pounds per square inch), and for L80 pipe, the minimum yield strength is 80,000 psi. This higher yield strength makes L80 tubing more suitable for use in challenging drilling conditions, such as high pressure and high temperature wells.

Another important factor to consider when comparing J55 and L80 pipes is their corrosion resistance. L80 tubing has better corrosion resistance than J55, making it the first choice for wells where corrosive elements are present. This enhanced corrosion resistance is attributed to the alloying elements present in L80 steel, which provide greater protection against the harmful effects of corrosive environments.

In addition to their mechanical and corrosion-resistant properties, the two materials also differ in their heat treatment processes. J55 pipe is typically normalized, which involves heating the steel to a specific temperature and then cooling it in still air. L80 pipe, on the other hand, is quenched and tempered, a heat treatment process that involves rapid cooling and then reheating to achieve the desired mechanical properties. This heat treatment process gives L80 tubing exceptional strength and toughness, making it suitable for more demanding drilling operations.

When purchasing J55 and L80 tubing, it is important to work with a reputable API 5CT J55 supplier or API 5CT L80 casing supplier. These suppliers are certified to provide materials that meet the stringent requirements of API 5CT standards, ensuring the quality and reliability of tubing and casing products.

To sum up, the difference between J55 and L80 pipes lies in mechanical properties, corrosion resistance and heat treatment process. J55 is suitable for shallow wells and less demanding drilling conditions, while L80 is better suited for deeper wells and more challenging environments due to its higher yield strength, better corrosion resistance and superior toughness. Understanding these differences is critical to selecting the correct tubing and casing materials to ensure the success and safety of oil and gas drilling operations.

Post time: Apr-25-2024