China Wholesale Tube Tee Manufacturers - LSAW Steel Pipe For Chinese Factories – Zhongshun

China Wholesale Tube Tee Manufacturers - LSAW Steel Pipe For Chinese Factories – Zhongshun Detail:

Used as low pressure liquid delivery pipes,variety of structural parts by the force and pressure as well as other purposes.

API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, GB/T3091, GB/T9711 ASTM A139, ASTM A252, JIS G3444 etc.

API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53: GR A, GR B, GR C

EN:S275, S275JR, S355JRH, S355J2H

GB:Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360- L555

Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test:Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

|

Nominal |

Nominal |

Outside |

SCH-5S |

SCH-10S |

SCH-20S |

SCH-40 |

|

150 |

6 |

165.2 |

2.8 |

3.4 |

5.0 |

7.1 |

|

200 |

8 |

216.3 |

2.8 |

4.0 |

6.5 |

8.2 |

|

250 |

10 |

267.4 |

3.4 |

4.0 |

6.5 |

9.3 |

|

300 |

12 |

318.5 |

4.0 |

4.5 |

6.5 |

10.3 |

|

350 |

14 |

355.6 |

4.0 |

5.0 |

8.0 |

11.1 |

|

400 |

16 |

406.4 |

4.5 |

5.0 |

8.0 |

12.7 |

|

450 |

18 |

457.2 |

4.5 |

5.0 |

8.0 |

14.3 |

|

500 |

20 |

508.0 |

5.0 |

5.5 |

9.5 |

15.1 |

|

550 |

22 |

558.8 |

5.0 |

5.5 |

9.5 |

15.9 |

|

600 |

24 |

609.6 |

5.5 |

6.5 |

9.5 |

17.5 |

|

650 |

26 |

660.4 |

5.5 |

8.0 |

12.7 |

- |

|

700 |

28 |

711.2 |

5.5 |

8.0 |

12.7 |

- |

|

750 |

30 |

762.0 |

6.5 |

8.0 |

12.7 |

- |

|

800 |

32 |

812.8 |

- |

8.0 |

12.7 |

- |

|

850 |

34 |

863.6 |

- |

8.0 |

12.7 |

- |

|

900 |

36 |

914.4 |

- |

8.0 |

12.7 |

- |

|

1000 |

40 |

1016.0 |

- |

9.5 |

14.3 |

- |

|

1050 |

42 |

1066.8 |

When dimensions other than those given in the alove-mentioned table are required,the dimensions shell be determined as agreed upon between the purchaser and the suppliers。 | |||

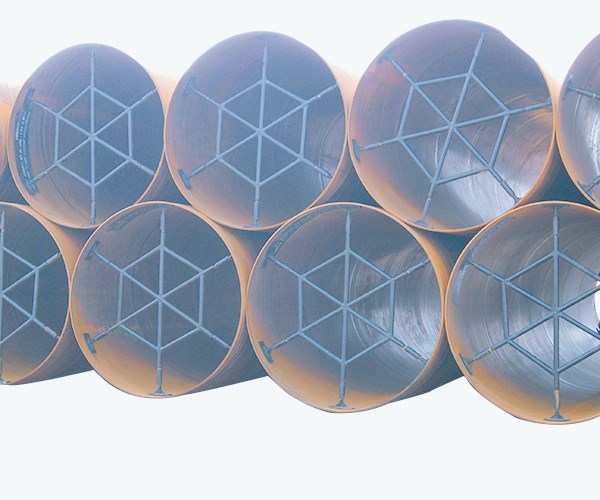

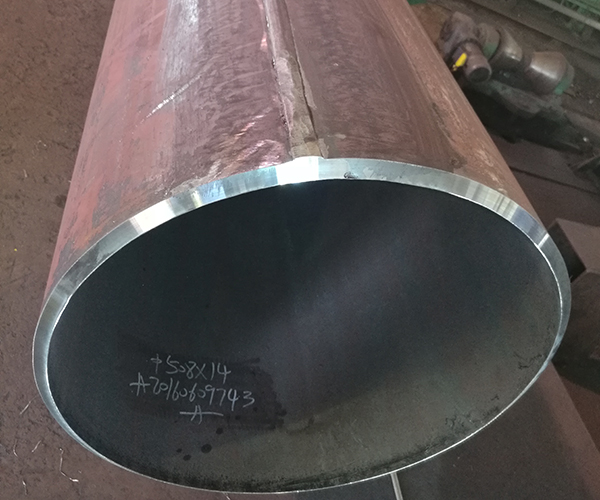

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for China Wholesale Tube Tee Manufacturers - LSAW Steel Pipe For Chinese Factories – Zhongshun , The product will supply to all over the world, such as: Serbia, United Arab emirates, Hungary, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!